Liquid metal can turn common items into smart devices: study

Study reveals scientists' successful attempt to turn items as ordinary as paper and plastic into smart gadgets

The idea of liquid metal being used to transform everyday materials into smart electronic devices may have been believed to be impossible a few decades ago, but currently it is an anticipated reality, reported SciTech Daily citing a study.

An innovative technique developed by Chinese researchers could completely alter the electronics industry.

According to a study published in Cell Reports Physical Science journal, ordinary materials like paper and plastic may now be converted into electronic "smart gadgets" by using liquid metal.

The research team, led by Bo Yuan from Tsinghua University, has created a simple yet revolutionary method to apply liquid metal coatings to surfaces that typically resist bonding with the substance.

The study demonstrates the potential of this strategy for large-scale use, opening doors to wearable testing platforms, flexible technology, and potentially soft robotics.

Yuan explained the significance of their discovery, stating: "Before, we thought that it was impossible for liquid metal to adhere to non-wetting surfaces so easily, but here it can adhere to various surfaces only by adjusting the pressure, which is very interesting."

Previously, liquid metal's high surface tension hindered effective binding with traditional materials, leading to difficulty integrating with traditional materials.

Yuan and the team looked for an alternative that would enable direct printing of liquid metal onto substrates while maintaining its characteristics in order to get around these restrictions.

Eventually, they coated various silicone and silicone polymer stamps with two distinct kinds of liquid metal, eGaln and BilnSn, and used differing pressures to rub the stamps across paper surfaces.

Fortunately, researchers achieved stable adhesion of a liquid metal coating to paper by applying a small amount of force and folding the paper into a paper crane, indicating that metal-coated paper retains its original properties even after folding.

Despite these great developments, Yuan noted that it is still difficult to guarantee the longevity of the liquid metal coating after application, yet the team is determined to create an alternative to applying packaging material to the paper's surface.

Yuan remarked, "Just like wet ink on paper can be wiped off by hand, the liquid metal coating without packaging here can also be wiped off by the object it touches as it is applied. The properties of the coating itself will not be greatly affected, but objects in contact may be soiled."

Furthermore, researchers plan to expand the method's applicability to a wider range of surfaces and construct innovative smart devices.

-

Total Lunar eclipse: What you need to know and where to watch

-

Sun appears spotless for first time in four years, scientists report

-

SpaceX launches another batch of satellites from Cape Canaveral during late-night mission on Saturday

-

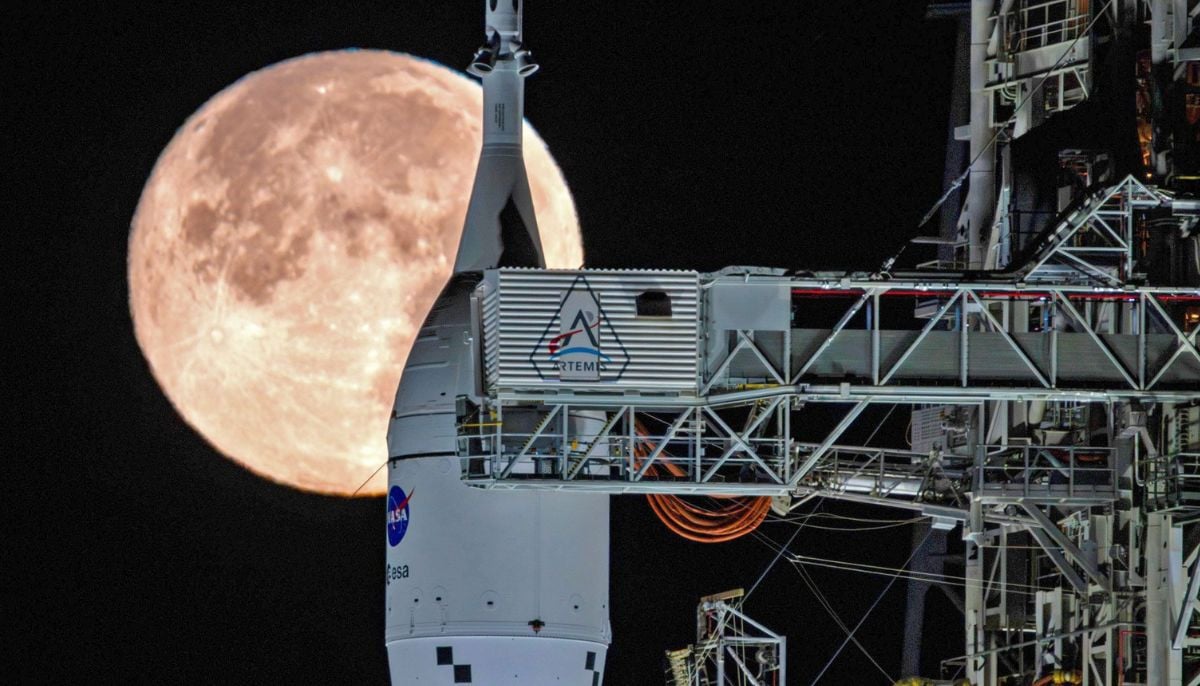

NASA targets March 6 for launch of crewed mission around moon following successful rocket fueling test

-

Greenland ice sheet acts like ‘churning molten rock,’ scientists find

-

Space-based solar power could push the world beyond net zero: Here’s how

-

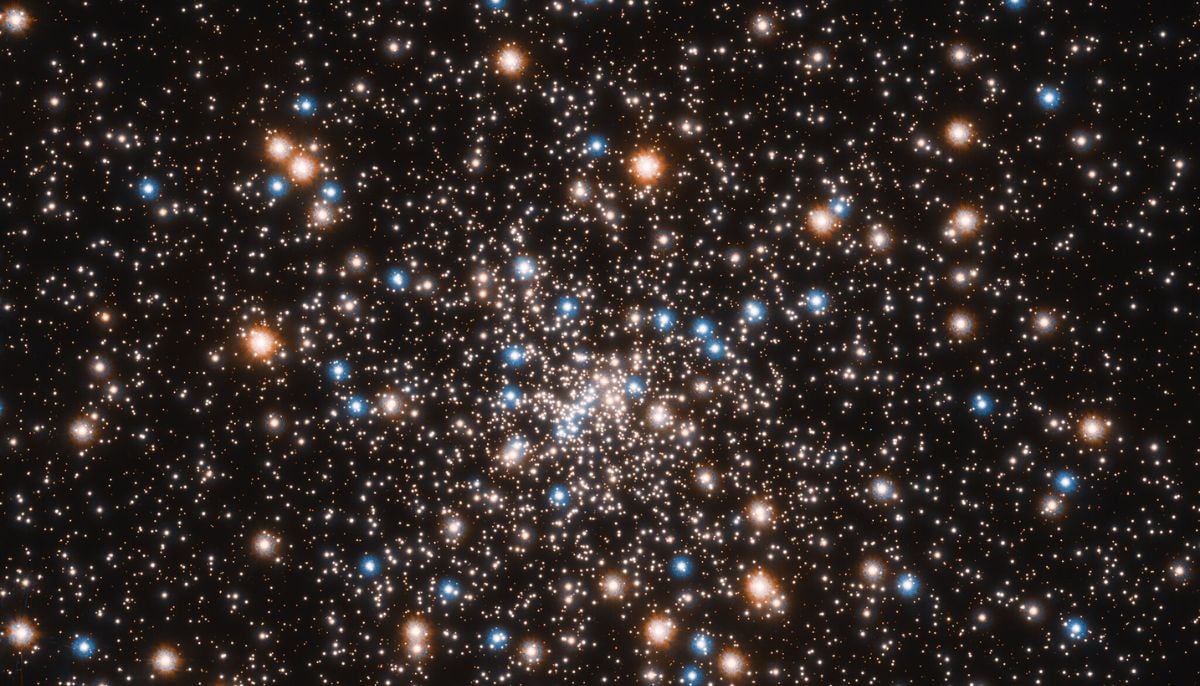

Hidden ‘dark galaxy' traced by ancient star clusters could rewrite the cosmic galaxy count

-

Astronauts face life threatening risk on Boeing Starliner, NASA says